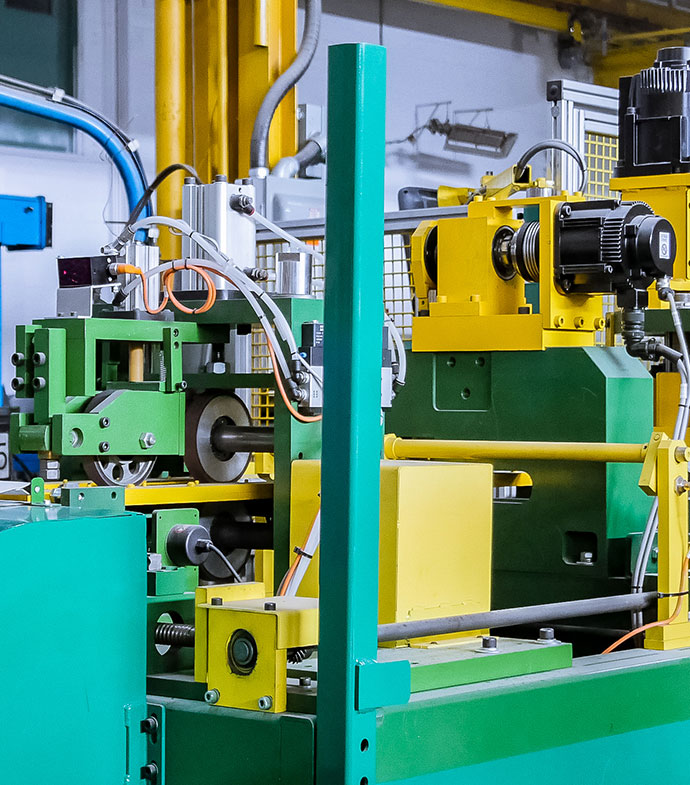

Core Cutting Machines

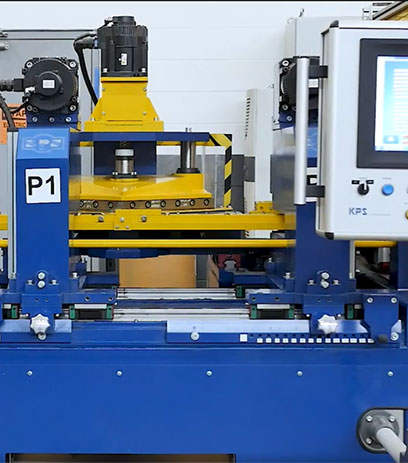

KPS offers standard or customized core cutting machine configurations.

Standard machines:

KPS CTL 250

Configuration

Swing-shear cutting line, with notch moving IN and OUT, fixed Punch, suitable for distribution transformer cores (Step Lap Mitre or Butt-lap), ranging from 50 mm width up to 300 mm. Equipped with two in-line magnetic stackers, with easy-offloading by crane or trolley.

Performance Specifications:

Up to 60 pieces per minute, depending on number of tools and configuration.

Features:

Single Headed Decoiler, with manual expand-and-collapse function

Above ground loop control

Feeder section with precision closed-loop measurement

Electronic jam detection and self-diagnostics

Servo controlled tool fire for Punch, V-Notch, and Swing Shear

Servo controlled helper feeder for eliminating material slack

KPS CTL 300

Configuration

Swing-shear cutting line, with notch moving IN and OUT, fixed Punch, suitable for distribution transformer cores (Step Lap Mitre or Butt-lap), ranging from 50 mm width up to 300 mm. Equipped with two in-line magnetic stackers, with easy-offloading by crane or trolley.

Performance Specifications:

Up to 60 pieces per minute, depending on number of tools and configuration.

Features:

Single Headed Decoiler, with manual expand-and-collapse function

Above ground loop control

Feeder section with precision closed-loop measurement

Electronic jam detection and self-diagnostics

Servo controlled tool fire for Punch, V-Notch, and Swing Shear

Servo controlled helper feeder for eliminating material slack

KPS CTL 400

Configuration

Swing-shear cutting line, with notch moving IN and OUT, fixed Punch, suitable for distribution transformer cores (Step Lap Mitre or Butt-lap), ranging from 100 mm width up to 600 mm. Equipped with two in-line magnetic stackers, optional bypass diverter, and offloading by crane or forklift.

Performance Specifications:

Up to 60 pieces per minute, depending on number of tools and configuration.

Features:

Two Headed Decoiler, with hydraulic expand-and-collapse function

*Optional 4 headed decoiler, or as-specified

Above ground loop control

Feeder section with precision closed-loop measurement

Electronic jam detection and self-diagnostics

Servo controlled tool fire for two punches, V-Notch, and Swing Shear

Servo controlled helper feeder for eliminating material slack

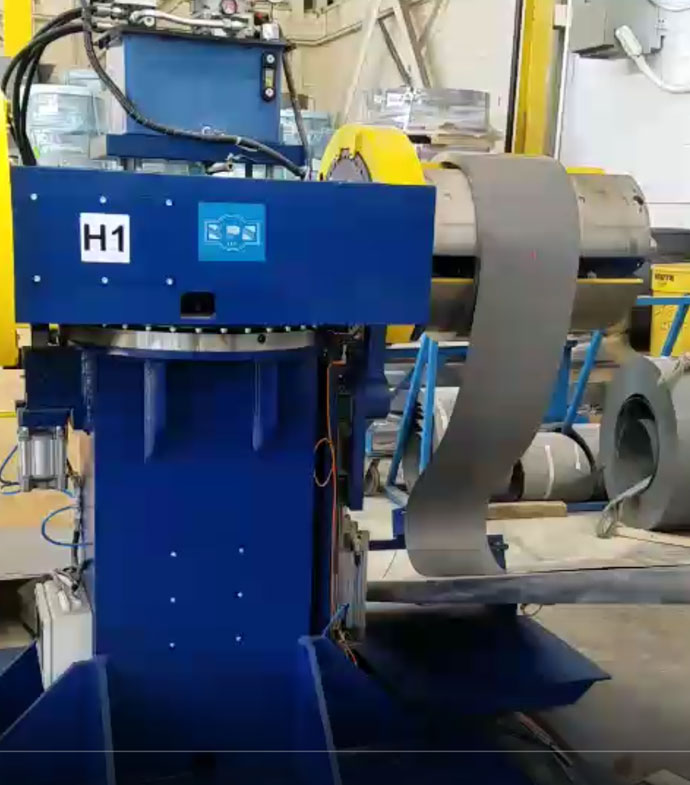

KPS CTL 600

Configuration

Swing-shear cutting line, with notch moving IN and OUT, fixed Punch, suitable for distribution transformer cores (Step Lap Mitre or Butt-lap), ranging from 100 mm width up to 600 mm. Equipped with two in-line magnetic stackers, optional bypass diverter, and offloading by crane or forklift.

Performance Specifications:

Up to 60 pieces per minute, depending on number of tools and configuration.

Features:

Two Headed Decoiler, with hydraulic expand-and-collapse function

*Optional 4 headed decoiler, or as-specified

Above ground loop control

Feeder section with precision closed-loop measurement

Electronic jam detection and self-diagnostics

Servo controlled tool fire for two punches, V-Notch, and Swing Shear

Servo controlled helper feeder for eliminating material slack

KPS CTL 600 Brochure

KPS CTL 600 Brochure